News 07/29/2024: With a good mood and a TOP CAPTRON team, we started this year's B2Run company run on Wednesday, 17.07.2024 at 7:00 p.m.

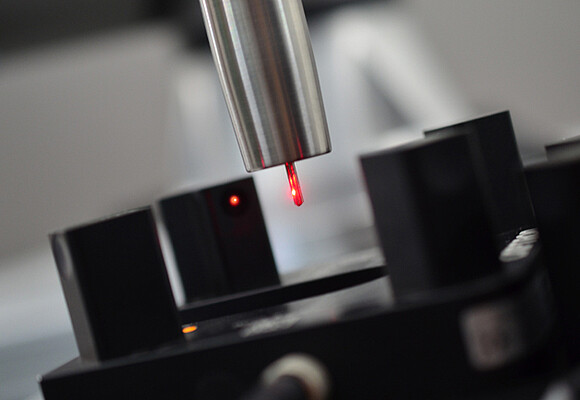

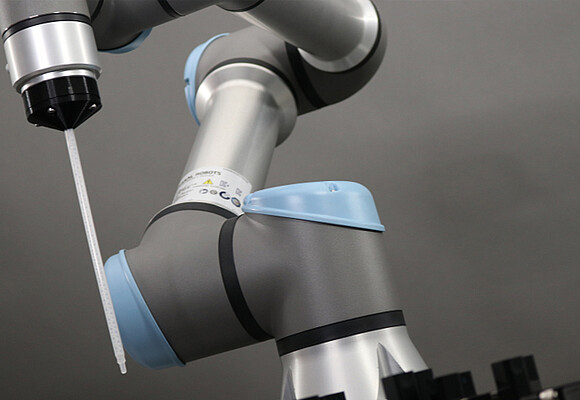

Maximum precision, minimum effort: Automatic TCP calibration for your UR Cobot

News 08/07/2024: In precise robot applications such as dispensing, welding and gluing, wear and deformation can change the accuracy of the robots.

To minimize downtimes in production and ensure maximum precision, the tool center point (TCP) must be checked and recalibrated regularly. This is particularly important after a tool change, after every maintenance, at the beginning of a work shift or even after each process cycle.

Benefits of automatic recalibration

- Minimization of downtimes: Automatic processes reduce production interruptions.

- Increased accuracy and quality: Regular inspections and calibration ensures the highest precision of your robot application.

- Reduction of rejects and rework: Accurate calibration minimizes errors, collisions and deviations in the production process.

- Reliable tool change: A quick calibration routine ensures the correct tool change.

- Unrivaled speed: Avoid manual reteaching with automatic recalibration.

Our solution for smooth processes: The automatic calibration of tool center points (TCP) for UR cobots. Thanks to our newly developed URCap software, you can reduce sources of error and avoid time losses in applications such as welding, dispensing, gluing...

Predefined motion sequences and control commands simplify programming. Our system has been tested and certified by UR.

Further information on the new product, downloads and videos on how to use the software can be found under the following link: Automatic TCP calibration from UR Robots

German

German English

English Chinese

Chinese Polish

Polish